The growth of modern industries relies on advanced production systems that create strong and precise components. Die casting plays a crucial part by shaping complex metal parts with consistent results. This method saves time while ensuring high strength across large production runs, making it vital for efficient product creation. Its adaptability supports multiple sectors, from small tools to large machinery parts, contributing to smooth operations worldwide through vietnam high pressure die casting.

Precision And Material Efficiency

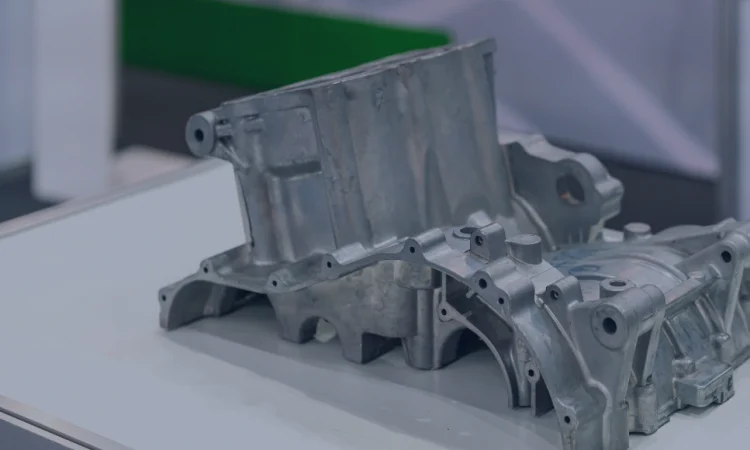

Die casting ensures exceptional accuracy in shaping intricate components with minimal waste. The technique allows uniform structures that meet exact standards in every production cycle. Manufacturers favor it for achieving fine finishes and dimensional precision across various metals. By using efficient molds, this process reduces resource loss while keeping superior quality.

Enhanced Production Capabilities

Modern industries depend on die casting to improve productivity and reduce operational time. It enables quick repetition without sacrificing strength or accuracy. Factories use automated setups that allow continuous output for consistent parts creation. This technique supports streamlined assembly, ensuring durable outcomes through every casting stage.

Cost Control And Sustainability

This process reduces expenses by cutting down material loss and maintenance costs. Its efficiency supports mass production without compromising performance quality. Die casting helps minimize scrap rates, promoting reuse of raw materials for greener outcomes. The integration of sustainable systems ensures long-term value in manufacturing sectors.

Applications Across Multiple Sectors

Die casting contributes to diverse industries where strength and reliability are essential. Its use extends to electronic housings, tool components, and industrial fittings. This technique supports modern innovation through flexible mold designs and reliable consistency. The impact of vietnam high pressure die casting enhances industrial standards across complex assembly lines.

- Produces identical components with reliable structural accuracy every cycle

- Reduces unnecessary energy waste through precise mold utilization

- Ensures sturdy surfaces that last longer under stress

- Helps create lightweight designs while maintaining required strength levels

- Supports advanced machinery for fast and repeatable production outcomes

Industrial growth today relies heavily on methods that maintain both quality and efficiency. By optimizing material usage and improving speed, die casting enhances production at every level. It delivers stable structures and lasting endurance, making it a key manufacturing technique. As industries keep evolving, precision methods like die casting will remain central to achieving reliable results that meet future demands.

FAQs

What are the main benefits of the die casting process today?

It creates precise parts quickly with minimal waste, ensuring strong quality.

How does die casting improve overall production consistency?

By maintaining exact shapes and sizes, it ensures uniform product batches.

Why is die casting preferred for large industrial projects?

It provides speed accuracy and durability within controlled manufacturing systems.